NEW CLASS

1 DAY STAINED GLASS FOR BEGINNERS

07/09/2024 - 1 place available

This is a 1 day class in which you will learn all the basic skills needed to create a stained glass panel.

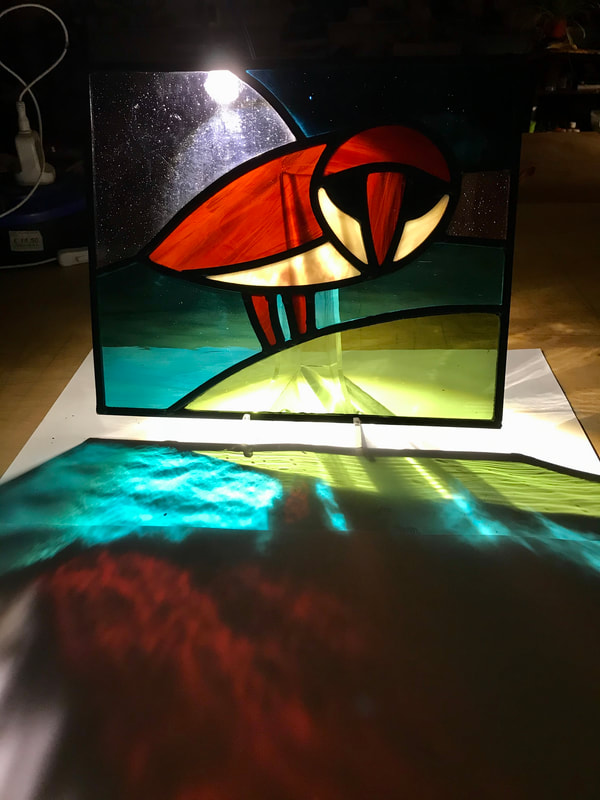

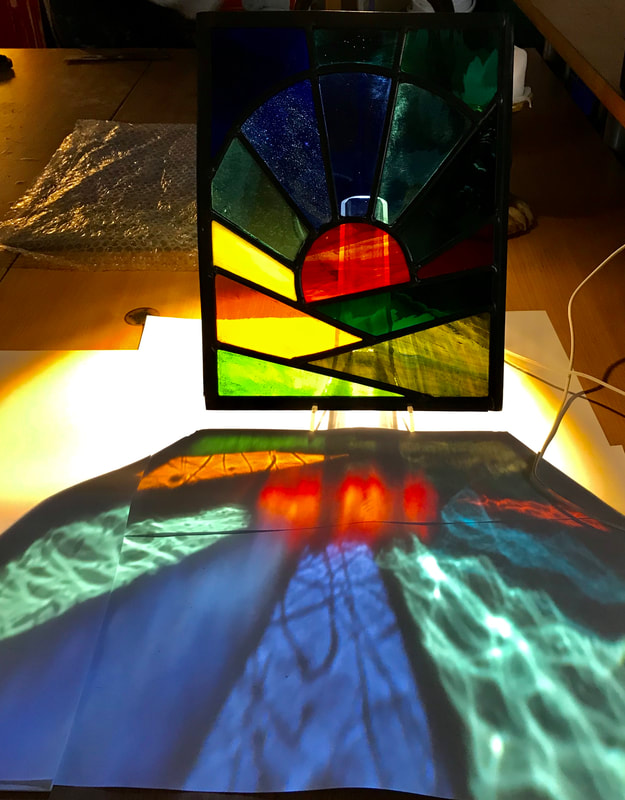

Stained glass is a beautiful thing to create and the way the light travels through the jewel coloured glass brings coloured light and patterns in to your rooms.

I have worked with glass for more than 30 years and am still delighted and excited by it.

On the day you will learn about design requirements, how to cut glass and choose your palette .

Once your glass is cit we will move on to lead work and grinding the glass in order to fit it all together.

Next is soldering and lastly cementing and cleaning the glass.

Its a busy day so come prepared to work hard and you will be so happy with the end result.

Because of the time this takes on this course there simply isn't time to create your own design so I have a number of pre made designs for you to choose from.

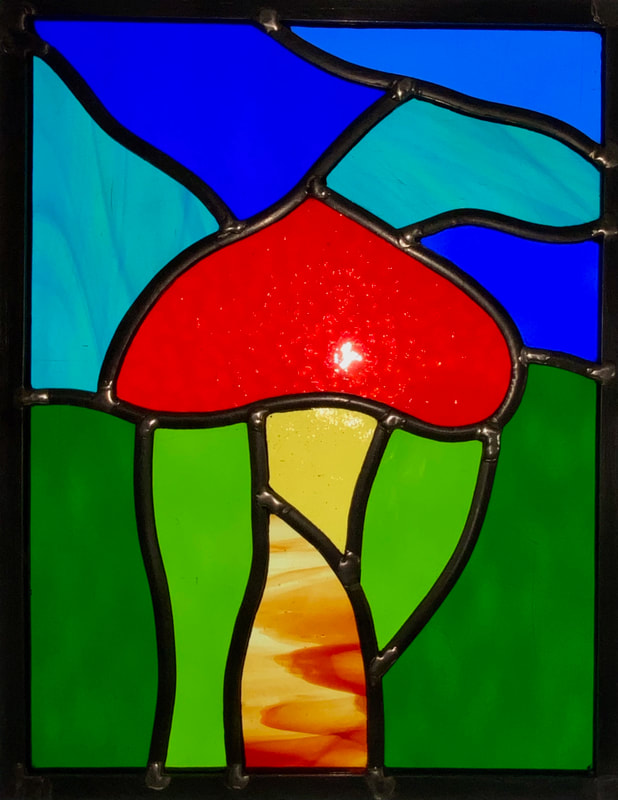

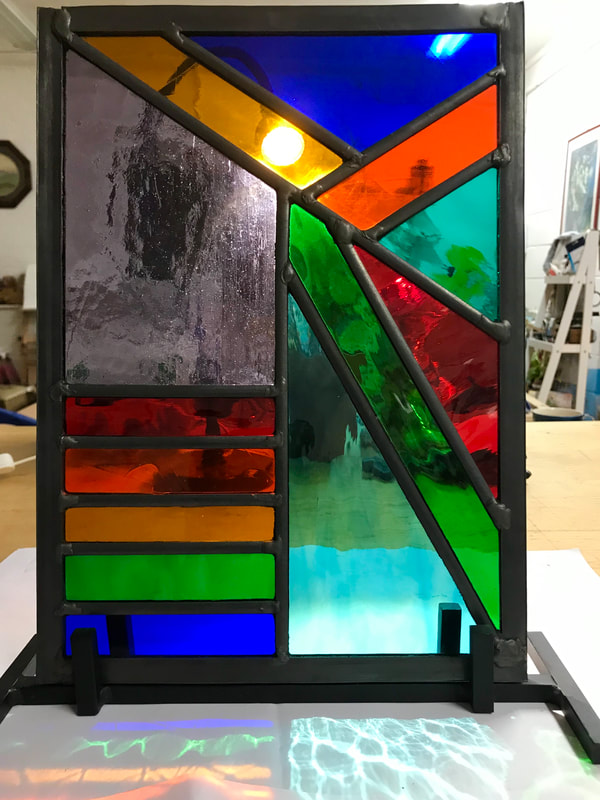

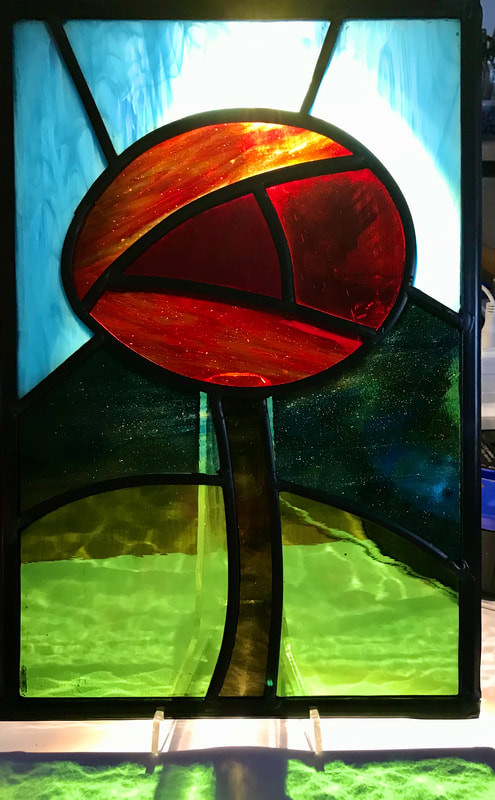

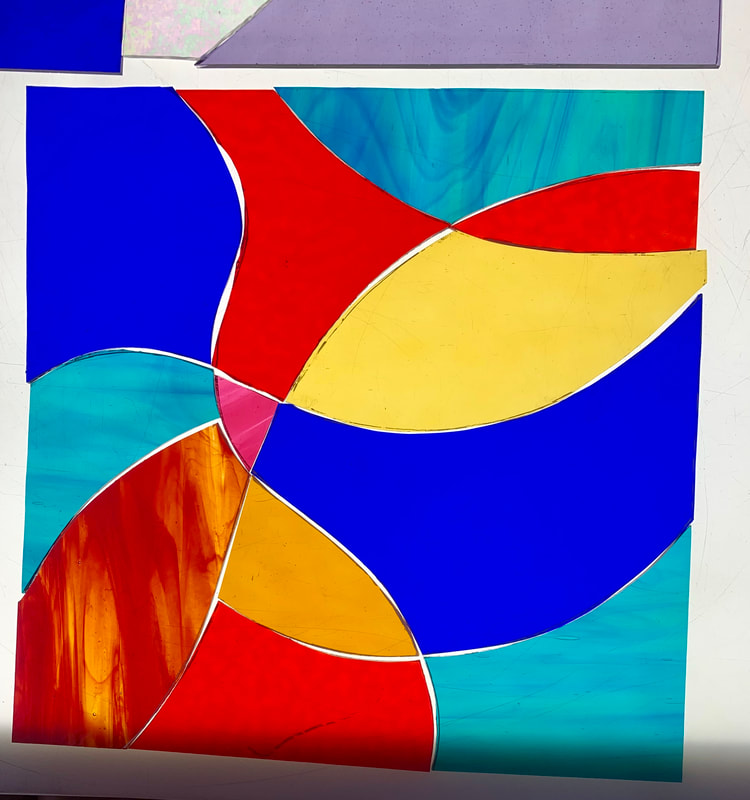

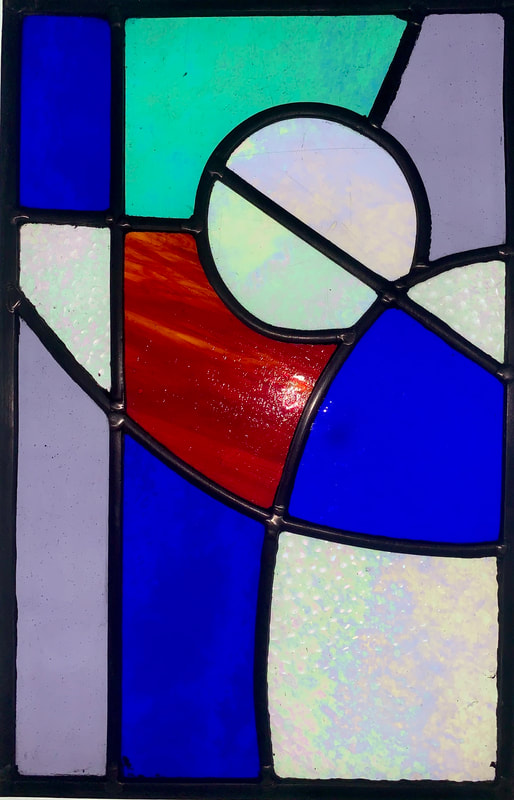

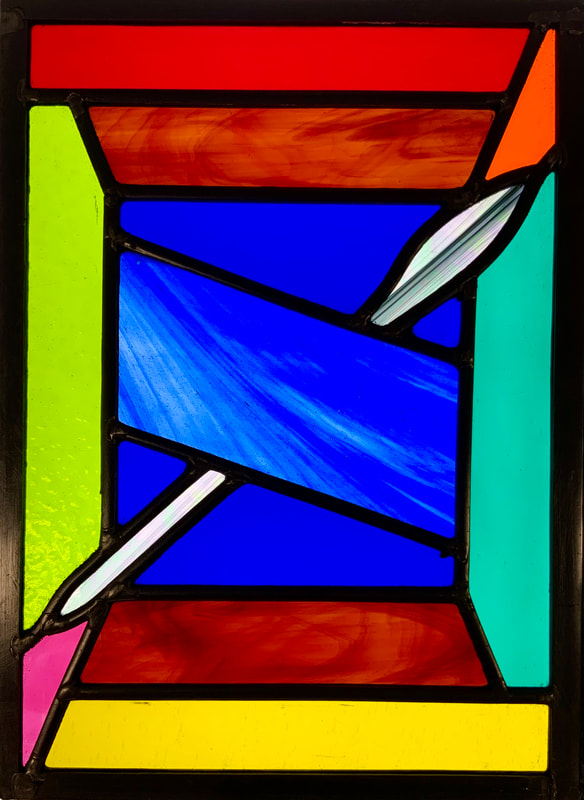

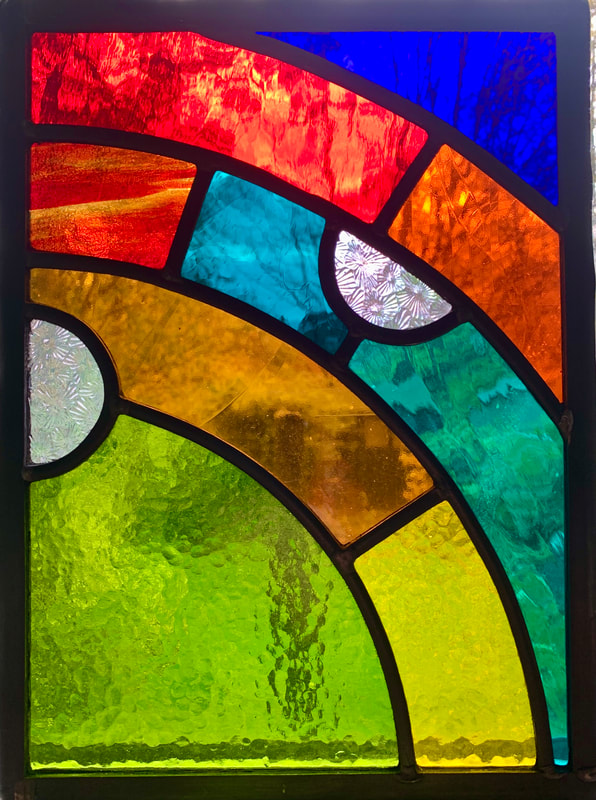

I have posted some images of previous class work to give you an idea .

Stained glass is a beautiful thing to create and the way the light travels through the jewel coloured glass brings coloured light and patterns in to your rooms.

I have worked with glass for more than 30 years and am still delighted and excited by it.

On the day you will learn about design requirements, how to cut glass and choose your palette .

Once your glass is cit we will move on to lead work and grinding the glass in order to fit it all together.

Next is soldering and lastly cementing and cleaning the glass.

Its a busy day so come prepared to work hard and you will be so happy with the end result.

Because of the time this takes on this course there simply isn't time to create your own design so I have a number of pre made designs for you to choose from.

I have posted some images of previous class work to give you an idea .

COST £150.00 PER PERSON

TIME 10.00 AM UNTIL 6.00 PM

VENUE HANNAHSTAINED GLASS

CONTACT [email protected]. [email protected]

TELEPHONE 07766394958

STAINED GLASS INTENSIVE WEEKEND

3 PLACES AVAILABLE £350.00

COST £350.00

DATE.

TIMES Friday 6.00pm-8.00pm

Saturday 10.00am-5.00pm

Sunday 10.00am-5.00pm

VENUE UNIT 7, UNITY BUSINESS CENTRE, 26 ROUNDHAY ROAD, LEEDS, LS71AB

CONTACT 07766394958

[email protected]

[email protected]

AVAILABILITY. 3 PLACES

DATE.

TIMES Friday 6.00pm-8.00pm

Saturday 10.00am-5.00pm

Sunday 10.00am-5.00pm

VENUE UNIT 7, UNITY BUSINESS CENTRE, 26 ROUNDHAY ROAD, LEEDS, LS71AB

CONTACT 07766394958

[email protected]

[email protected]

AVAILABILITY. 3 PLACES

This weekend course is an introduction to the art of stained glass.

I will keep this class size small, three places, so all of you get enough 1 to 1 teaching.

You will learn all of the skills required to design and make a stained glass window.

The class begins on Friday evening and this session is dedicated to designing your panel.

We will then spend the rest of the time cutting glass, leading, soldering and cementing your panel.

The finished result will be a unique stained glass window that is all your own work, below are examples of former participants pieces.

All materials are provided apart from rubber gloves, an old toothbrush and a white marker open, Posca pens are good. These items you will need to bring.

It’s a good idea to bring a packed lunch. Tea and coffee are provided

Wear comfortable clothing and no open toe shoes please and if you need to wear glasses please bring them with you.

PLEASE NOTE: This course is not suitable if you are pregnant or breastfeeding because you will be handling lead and solder.

CONTACT [email protected]. Tel 07766394958

"Jo was a fantastic and thorough teacher, patient and understanding and always ready to help with any problem. I’ve learnt so much over this weekend, from cutting glass, leading, soldering and cementing, and I‘m eager to do it again. This course is definitely the best place to learn - Jo’s skills are incredible and her workshop is beautiful - a wonderful way to spend the weekend, thank-you again!!"

Catherine

Catherine

|

|

TERMS AND CONDITIONS

Cancellation

In the unlikely event that I have to cancel a course you will be offered to transfer your place to another date or receive a full refund. |